Rebuilding the Brake on a Warn 8274 Winch

I recently purchased an old 8274 winch. It was working, but had seen a few years. I found the brake rusted up solid. If your rig sits outside, I would seriously suggest getting a cover. The brake parts that sit outside have no sealing and are all made of steel. The inner brake disc needs to slide on the shaft to allow braking.

Mine was a serious bear to disassemble. If you find yours is really on there, I would suggest removing the assembly and taking to to a press for removal of the brake from the shaft. I was stupid and spent many hours trying to fight it off the shaft.

Anyway, here is a ruin down of what is involved. Note that I took the pictures on assembly (that is why everything is cleanish). Click on the pictures for larger images. I should add that this winch is an early model (S/N 135012). Later models have some variations in the brake components, but nothing to worry about.

Disassembly

- Remove winch from rig. Trust me, assembly is a serious PITA with the winch horizontal. It really is best to have it on its side.

- Put clamp on the

brake assembly to prevent it coming apart. Put winch on side and

remove circlip. If you are lucky, you can release the clamp and

it will all come apart and you can skip to #4. If not lucky

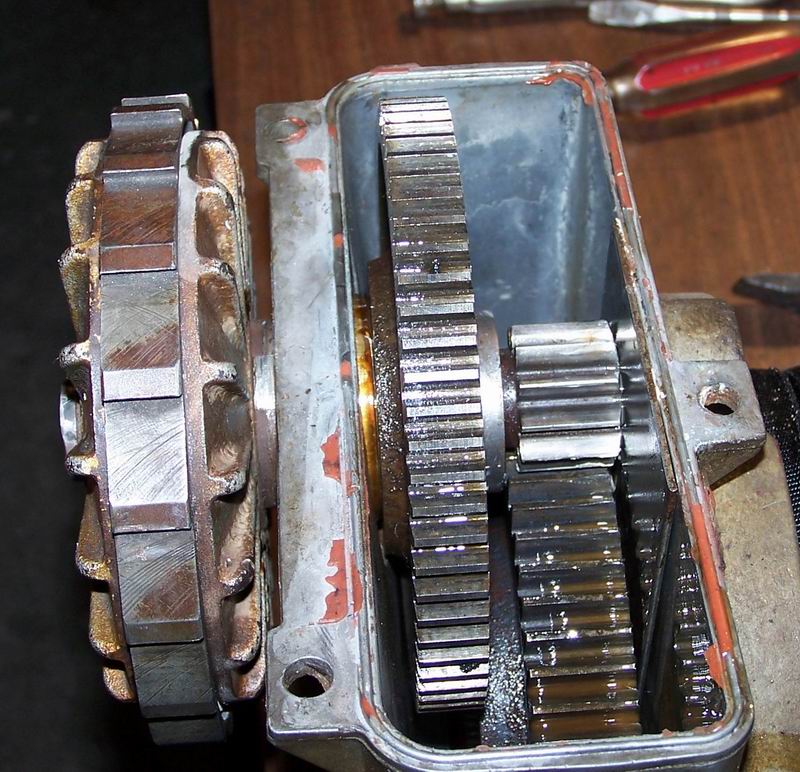

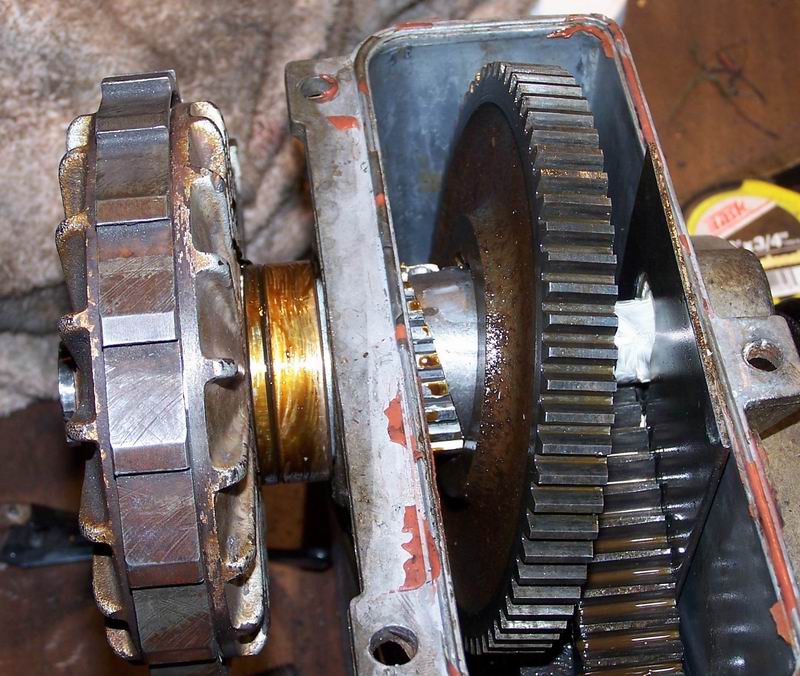

remove the upper housing (3 allen keys). You will find this.

- Lift the retention plate on the inside of the winch to free the brake shaft. Tap the assembly out to free the bronze bushing from the housing.

- Remove and clean all brake components. The following pictures set shows the disassembly.

Brake

complete at start

Brake

complete at start Outer

Disc removed showing outer friction material, ratchet, ratchet bearing

balls and inner spacer/bearing race.

Outer

Disc removed showing outer friction material, ratchet, ratchet bearing

balls and inner spacer/bearing race. Inner

disc, inner friction material and spacer.

Inner

disc, inner friction material and spacer. Inner

disc and spring

Inner

disc and spring Shaft

with splined cam, bushing and lip seal.

Shaft

with splined cam, bushing and lip seal. Bare

brake shaft.

Bare

brake shaft.Some people have also found problems with the snap ring coming off in use. This is not a good thing as the brake does not work. A good solution is to drill and tap the shaft and then bolt on a retention plate as a backup to the snap ring. Here is mine installed. I've made a disc from 1/4" carbon steel and held it in place with a 3/8" UNC bolt. The spacer between the plate and the snap ring is a regular galvanized 1" flat washer (perfect fit).

Assembly

- Put the shaft with the spline cam back into the housing and put

the locking plate back down. Make sure the cam is in the released

position.

- Tap the bronze bush back into the housing. Note it protrodes in slightly to locate the brake driven gear. The gear will hit the housing on the outside without the bush holding it.

- Tap in the lip seal.

- Put the winch on its side and reassemble the brake components in reverse order.

- Clamp the discs together to compress the spring.

- Insert the circlip. Make sure it is properly seating.

- Bolt on the retention mod.

Later winches, S/N 620968 and up parts lists are here.

Billavista's Great rebuild writeup here

S/N 337834 and lower Part list here

S/N 344816 to 620968 here

Updated 2005/10/13